CZ457 LRP rifle makeover

Introduction

There is that moment when you still have the opportunity to back out of a project. But then, what is the worst that could happen? For one, I could mess it all up, and end up binning the stock. But nothing ventured, nothing gained…

Before we start, why am I doing this CZ 457 LRP (Long Range Precision) makeover again?

It was to:

Add a longer bag rider, one that is flat and will not get tangled on everything. Improve the balance of the rifle. Have a more flexible solution for the bipod positioning on the rifle. And to give my CZ 457 LRP a new unique look.

Components I decided to use

After researching many options and suppliers, I decided to go with the following:

Paint job

I like the look and feel of Carbon Fiber, and for this project, I have decided to do a Carbon Fiber wrap of the original LRP beechwood stock. However, Carbon Fiber alone could be dull. Adding a few splashes of colour to break it will solve it, and give me the option to hide areas where the weave distorted.

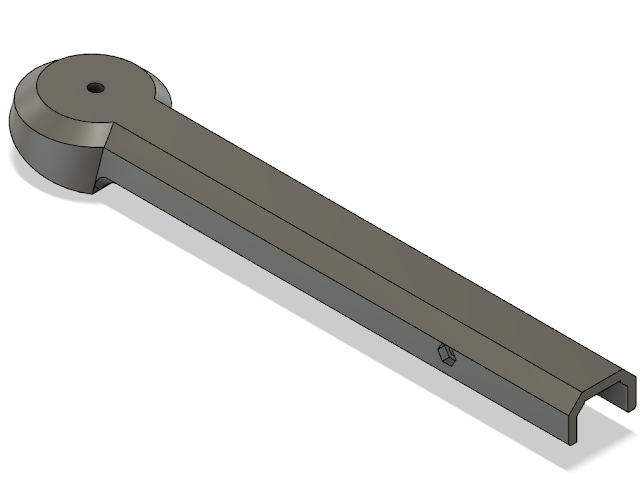

Bag rider

After doing research on available bag riders, I could not find one that worked for me. That led me to decide to design a custom bag rider in Fusion 360, 3D print it and then wrap the 3D printed bag rider in Carbon Fiber to match the stock and its paint job.

Balance

The beechwood stock is heavy, which means the front end of the rifle needs more weight to balance things out.

I could drill holes in the barrel channel of the stock, and epoxy weights in there, but it would mean that I might have to drill more holes or try to remove weights in future if I changed the barrel. I decided this was not the best option.

One of the suppliers I looked at was Area 419. Their Universal Weight-Tunable ARCALOCK Rail will give me a flat surface at the front of the rifle, to make the rifle more stable when shooting over obstacles without a bag, and it will open new options for where to attach a more sturdy Tripod and Bipod on the rail.

Area 419 also offers an ARCALOCK Fixed Barricade Block, which will protect the magazine and thus minimise feeding issues.

Bipod

I love my Harris Bipod, and I used it with an adapter to fit a Picatinny rail. Again, Area 419 has a Harris Bipod ARCALOCK Clamp Kit that fits the new rail and my existing bipod.

Let’s get on with it

No turning back now! Now we get to the part where the rubber meets the road. What follows, is how I did my CZ457 LRP Rifle Makeover (with the understanding that there could be better ways to do it, but this is my way and you can see the results I got doing it this way).

Bag Rider design and print

I took the necessary measurements, and after a couple of iterations, I had a bag rider that resembled what I envisaged in my mind. My design uses the existing rear picatinny rail and extends all the way to the grip, giving a long flat surface for a rear shooting bag.

Next is to 3D print it, and see if it fits. And, of course, it did not fit the first time, or even the second time. By the third time I got it right, and there was all-round happiness in my garage!

I used a 0.6mm printing nozzle, printing at 0.15mm layer height using PLA.

I did consider using PETG instead since it can withstand more heat than PLA, but then, it will be wrapped in Carbon Fiber and should not warp in direct sunlight. It will be secured at both ends, which means it will not go anywhere (what I told myself).

Stock Carbon Fiber wrapping and paint

Preparation

Preparation is everything. And there is no easy way around this. It takes elbow grease and time.

I used 80-grid sandpaper and a soft block to remove the soft touch of grey paint.

I did not worry too much about losing the textured areas as it was going to be covered by the Carbon Fiber, but I did want to make sure there would be sufficient roughed-up surfaces where the resin could bite into.

The soft-touch Grey paint is impressively tough though, and it took a fair amount of work to remove it - kudos to the CZ team for treating their rifle stocks with high-quality abrasive-resistant paint.

After cleaning all the dust off the bare stock, it is time to plug up all the openings. I used children’s clay that I bought from the local $2 shop. Worked as I hoped it would.

This is the extent of the preparation, and now it is on to getting Carbon Fiber onto the stock.

Wrapping

Before applying the Carbon Fiber cloth, I mixed black pigment into a small mix of resin according to the manufacturer’s specifications, to use as an undercoat. This will give the Carbon Fiber a solid black background and hide areas where the cloth is stretched to the extent that it will expose the wood underneath.

The first coat (or black undercoat) is a thin layer.

Keeping track of the time and the curing of the resin is important. You do not want to let the resin cure beyond the B-stage as it should act as the “glue” to stick the Carbon Fiber cloth onto the stock.

B-stage is when the resin is sticky when you touch it. It will leave a fingerprint, but it will only come off onto your finger if you press and hold for a couple of seconds.

Applying the cloth is reasonably straightforward. Start with the areas that will be most visible and then work your way into the smaller nooks and crannies. Slowly drape the cloth over the sticky area while gently pushing it down into the resin.

Take note though, that once the cloth touches the sticky resin, it can not be removed without disturbing the weave pattern. Patience and working slowly are key.

Once the cloth is on, let it cure before adding a layer of resin. The aim at this point is to thoroughly wet the cloth, but not to the extent where the resin runs.

Let the first layer cure overnight.

I used 180-grid sandpaper and a wooden block to level the surface. But you do not want to break into the cloth. Again, patience and working slowly are key and keep an eye out for when the dust turns black as it means you are busy sanding into the Carbon Fiber cloth.

Once done, clean the stock with a damp microfibre cloth.

Add three (3) more layers of resin. Wait for each layer to reach the B-stage before applying the next layer. Timing is important for the three resin layers you are building up. It is important that you do not let it go beyond B-stage or it might not bind as to the last layer as it is supposed to do. In my case, it was about 2 hours between coatings.

Let it cure. I left it for a couple of days.

I started with 280-grid sandpaper on a wooden block and worked my way up to 1200-grid. The aim is to create an even and smooth surface before adding the last thin layer later on.

This is the best time to do all the cutouts and openings. I used a Dremel with a cutting disk to cut the openings under size. Thereafter I used a drum disk to clean all the edges.

Remove all the clay.

It is a tedious job, and you have to be extra careful as the areas where the Carbon Fiber was cut leave unsafe edges that cut like a knife!

Clean the barrel channel and the rest of the openings with a clean cloth. Remove all the clay residue from the action screw holes and the recoil lug area.

This is a good time to test-fit the action and trigger guard to see where there are areas you missed that stand proud and will cause the fit to be less than perfect.

I installed QD-CUPS into the front of the stock a long time ago, and I decided it was something I wanted to keep after the rifle makeover. Drill the holes a mitch bigger than the QD-CUPS you want to install and epoxy them in place.

Tape up the stock with masking tape, and rattle-can spray the exposed areas. The purpose of doing this is to make the inside parts (that might be visible) have the same finished look.

Mix a small batch of resin, and paint the last extra thin layer. This is a thin layer and you do not want the resin to run. At this point, you will get a good idea of how the rifle is going to come out. If it looks good now, you know it will look great when you are done.

Use 1000+ grid and wet sand the whole stock. Now it is the last change to take all the ripples out of the resin layers.

And we are in the home stretch!

With my skill level, and all the effort I put in, I ended up with a spot or ten I was not happy with. I want it to be perfect, but this will have to do.

Add colour and hide the blemishes

I opted for the sponge paint look. Start with the brightest colour first (in my case I selected Yellow).

Focus on areas where the cloth has distorted, or where there are pocks and spots where you might have broken through the cloth in the earlier sanding stages.

Tone the bright colour down with a darker colour (dark Gray in my case)

Once the colour paint was on, I covered it in three (3) layers of a satin clear coat. I have used Rust-Oleum, but anything with UV protection will be good. The best result from this is that it makes the small imperfections that were there disappear, and you are left with a great-looking finish.

Just to mention, I did the painting on both the stock and the Carbon fibre-covered Bag rider at the same time.

Installing the ARCALOCK Rail, Fixed Barricade Block and Harris Bipod Clamp Kit

Now we are ready to put the rifle back together again.

Many of you reading this might cringe at what I do next.

I do not like it when the ARCA rails protrude in front of the stock. I want it flush. In my case, I decided to modify the Area 419 ARCALOCK Rail at the back end of it, to enable access to the front action screw while being flush to the front end of the stock.

I polished the exposed area of Area 419 ARCALOCK Rail with 800-grid sandpaper to give it a professional finished look.

(yes, yes, I know, I have been told many times before that I have issues)

Conclusion

I have successfully scratched my itch, and I am very happy with the results. So much so that I decided not to buy a chassis in the short to medium term. Sometimes I wondered if this would work out, but things tend to look worse before they look better.

Taking a closer look at the finished rifle:

Bag rider

Nice long straight surface area that gives me many options for where I place the rear bag.

Balance

Using the Area 419 Universal Weight-Tunable ARCALOCK Rail I could play with the weights until the balance point was at the barricade stop.

Bipod

Fitting the ARCALOCK kit was easy with good instructions supplied with the kit. I like the ARCALOCK concept as the bipod will not slip around.

Other

Apart from the changes I mentioned above, I installed an EC Tuner at the same time. The reason for doing it now is that is what I am planning the run this rifle next season and I wanted to get the balance right with it in place.

I will do testing with the EC Tuner and share my results sometime in future.

Tips based on my experience during this project:

- When you apply the Carbon Fiber cloth, it is good to have someone help you.

- Make peace and move on if the cloth does not sit perfectly in place. It might not be visible in the end when you do the cut-outs later on. Do not sweat the small stuff.

- Make sure you have enough time when you have to wait for B-stage. You want to get this right, so plan ahead.

- Depending on the resin you use, you might have to use a heat gun to heat the surface of the area where you applied the resin to remove the small air bubbles. Just a little bit of heat though. The bubbles will be visible if you don’t. You can also use resin that is less prone to trap bubbles which will make your life easier.

- Get a box of disposable gloves, disposable cups and mixing sticks. It gets messy quickly.

- Wear PPE. You do not want to breathe the Carbon Fiber dust and resin fumes, or worse get those little splinters in your eyes.

- Lastly, on QD-CUPS. The ones I installed had a small hole in the bottom. After I covered them in epoxy and dropped them into place, I saw that a lot of epoxy pushed through the hole into the cup area. I am glad I spotted that happening as it would have rendered the QD-CUP useless once the epoxy hardened inside the cup. I cleaned them out with cotton sticks and a bit of oil.